BULLSEYEBORE CORE - FAQ

Table of Contents

❶

What is BullseyeBore Core?

BullseyeBore Core is a patented power drill accessory that helps you to always drill straight (which means perpendicular to the worksurface).

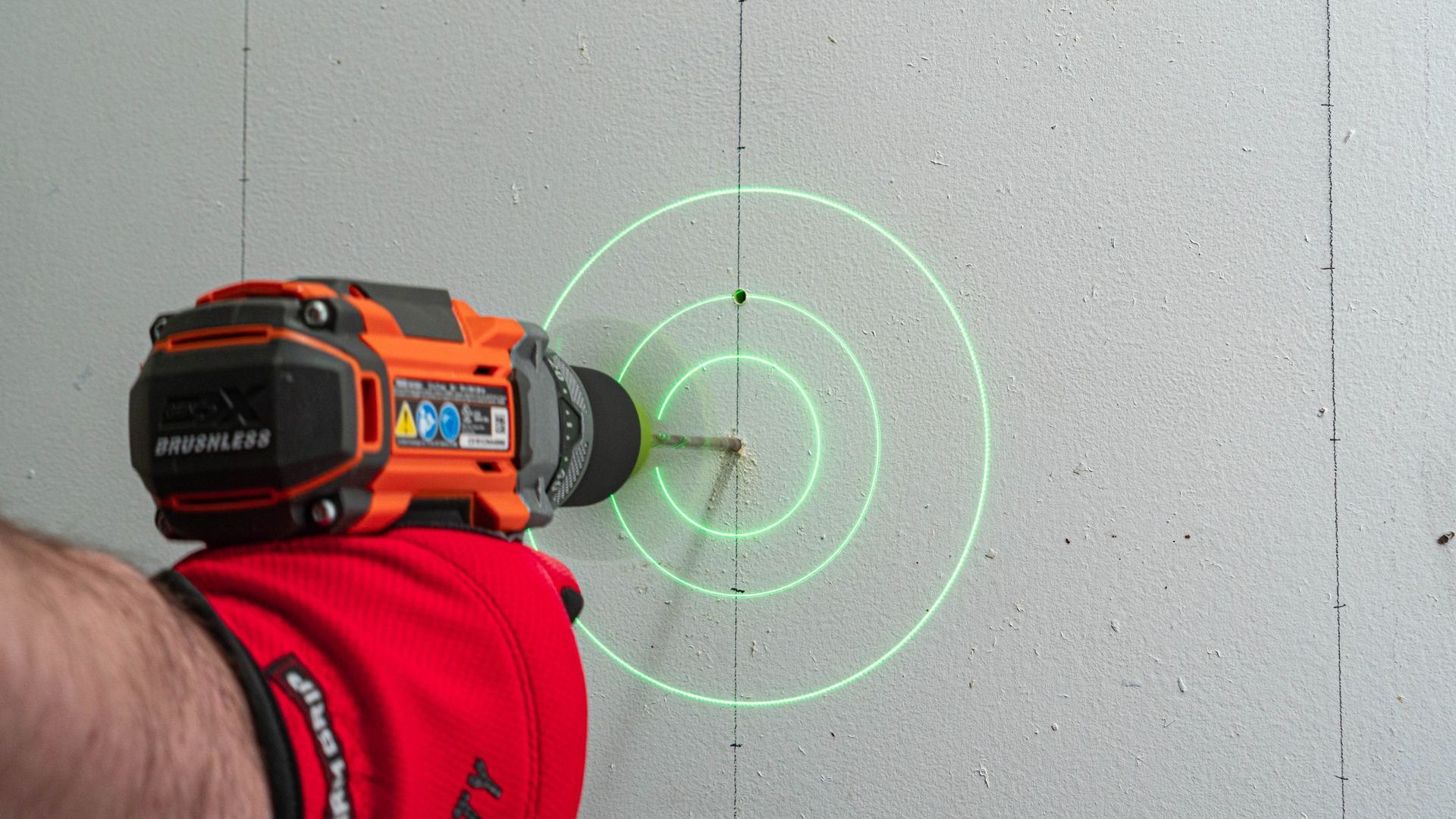

The “Core” is designed to work seamlessly with common electric drills by mounting magnetically to the flat front face of the drill chuck. When the drill rotates, BullseyeBore Core rotates at the same speed and projects a series of circular patterns on the work surface that indicate alignment or misalignment of the drill bit with regards to the work surface. When the patterns are concentric, the drill is straight with (and perpendicular to) the work surface. Conversely, when the patterns are non-concentric, the drill is misaligned with the work surface. These patterns make it easy for DIYs and Pros alike to always drill straight. BullseyeBore Core works in any orientation, so it can easily be used on walls, floors, ceilings, or boards at any angle. The Core’s unique shape also allows it to be virtually invisible during drill rotation, so the drill bit, work surface, and the Core’s projected work surface patterns are clear and easy to see. Moreover, BullseyeBore Core’s unique magnetic connection to the chuck face makes it safe to use. If a foreign object mistakenly comes into contact with BullseyeBore Core during rotation, the magnetic connection between the Core and the drill chuck is immediately broken, and the Core’s rotation ceases (even if the drill bit is still spinning). The magnetic connection also makes attachment and detachment quick and easy. Unlike other drill alignment solutions, the Core is also contactless and does not touch the work surface, so there is never any danger of marring or denting the work surface. BullseyeBore Core and our related technologies are either patented or patent pending in the US and/or internationally.

❷

How does BullseyeBore Core work?

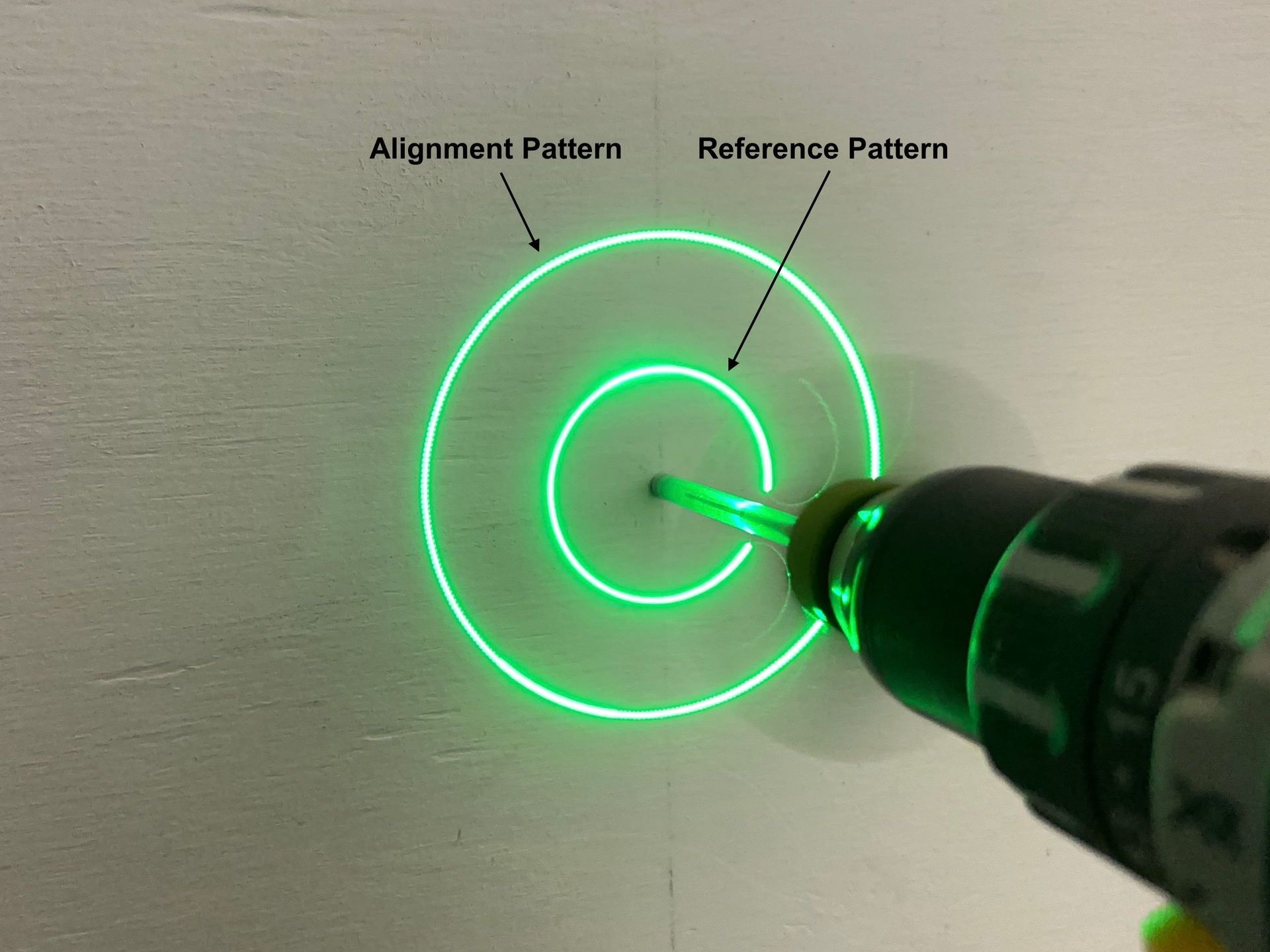

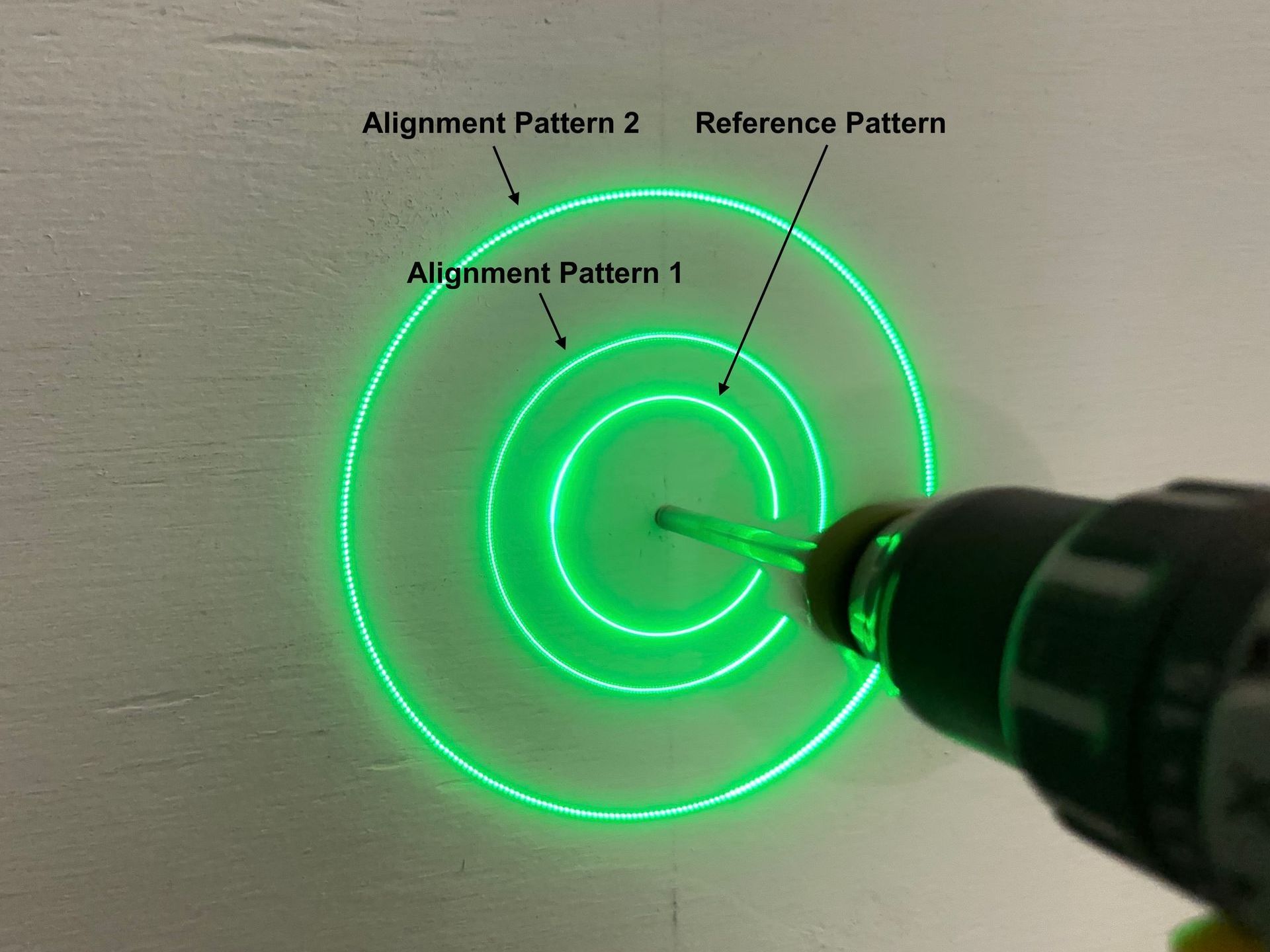

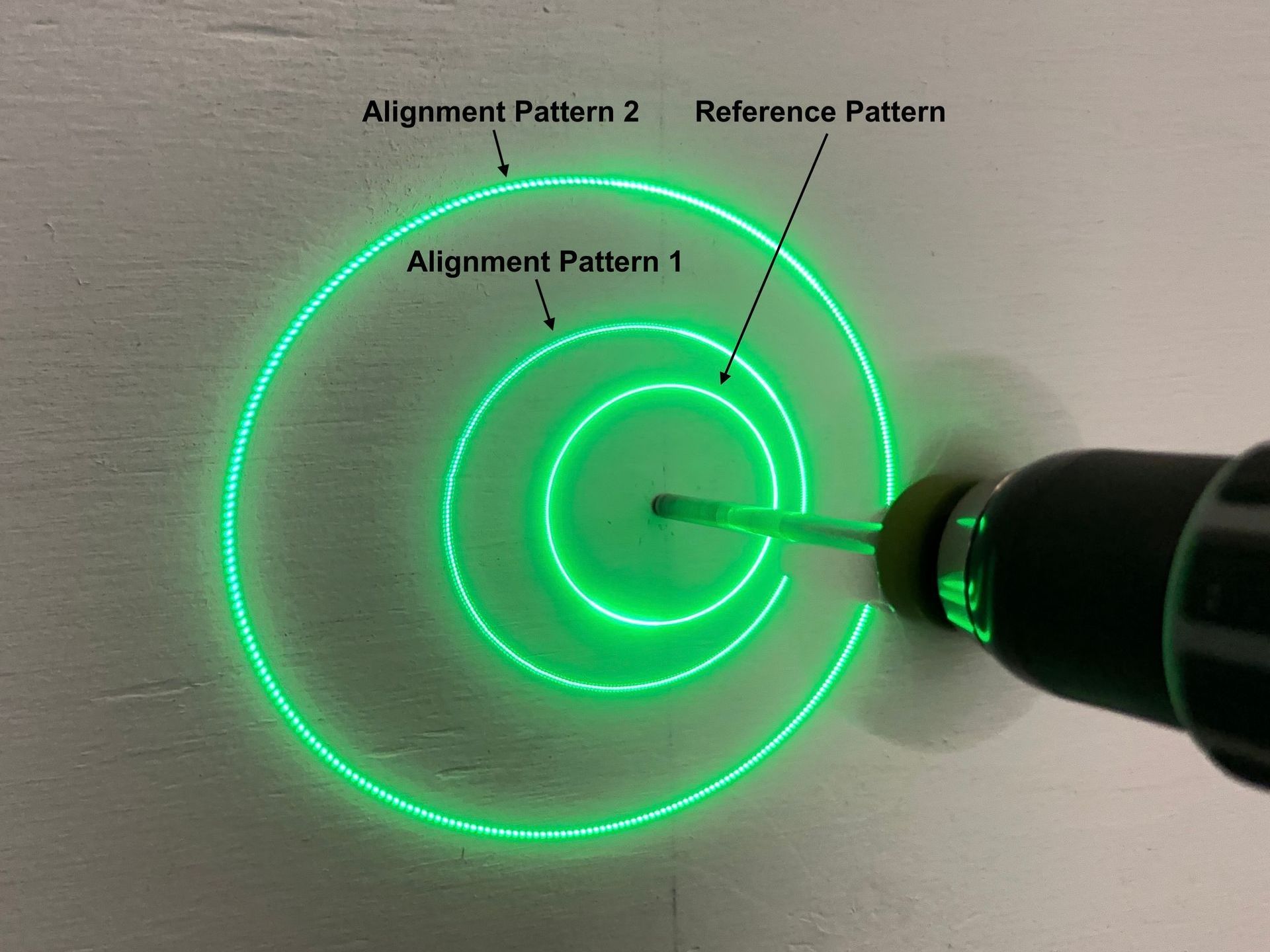

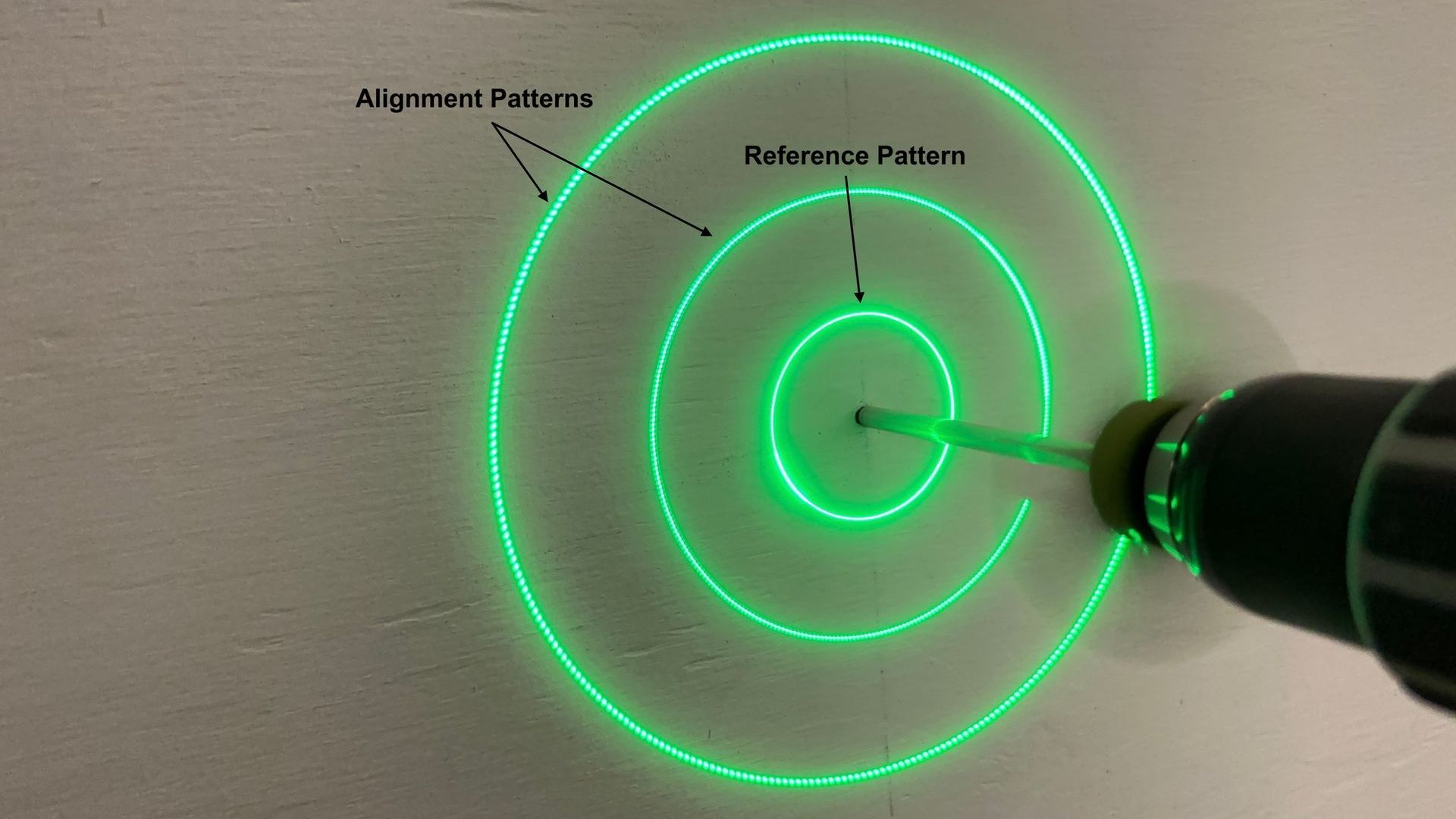

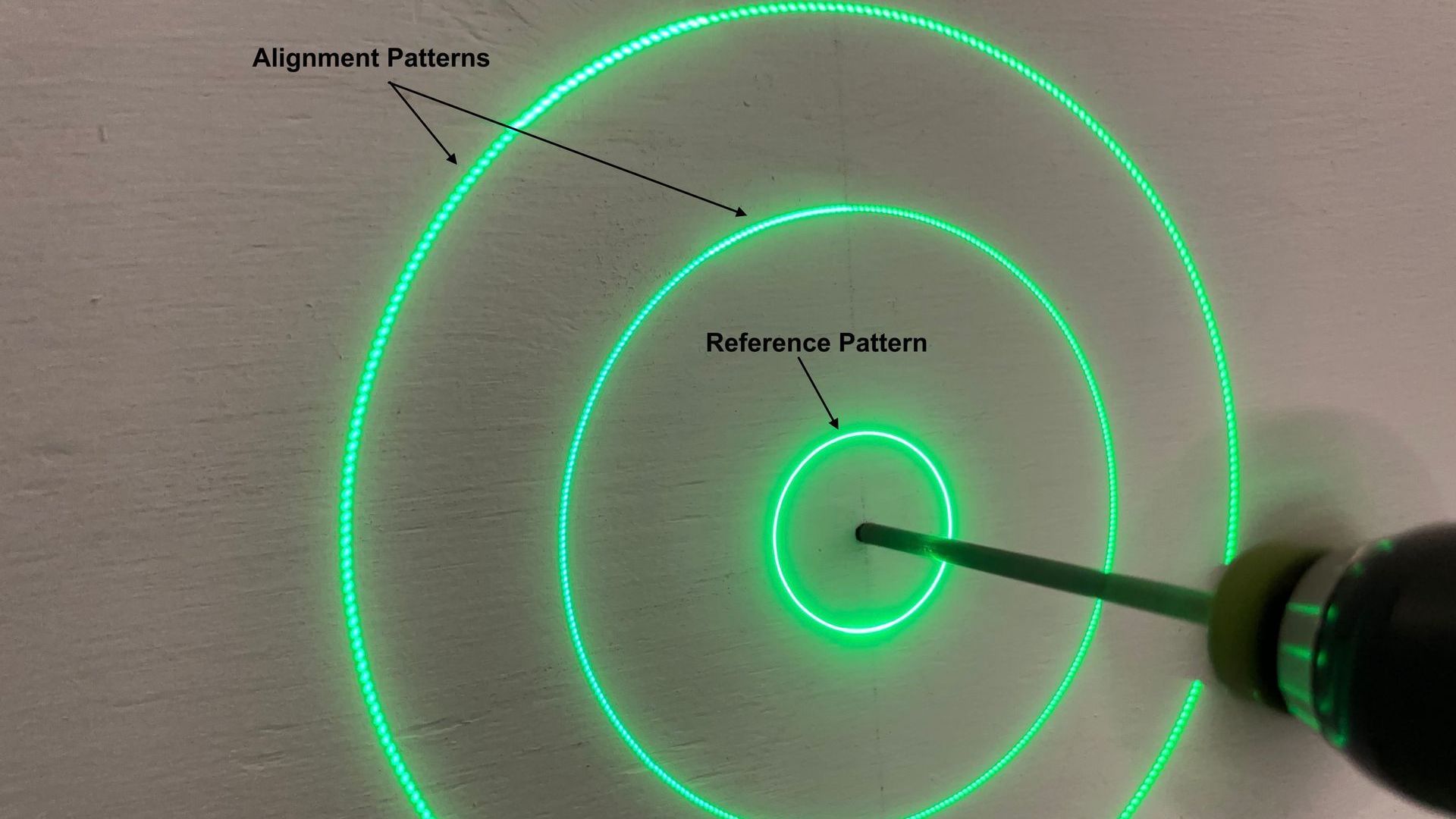

The standard versions of BullseyeBore Core (CR1-100 and CG1-100) projects two beams on the work surface that produce circular patterns during drill rotation. The first beam is projected parallel to the drill bit. This projection is known as the Reference Beam, and this beam produces a circular Reference Pattern on the work surface while the drill is rotating. The Reference Pattern is generally circular and unchanging even if the drill is misaligned (tilted) with reference to a flat work surface.

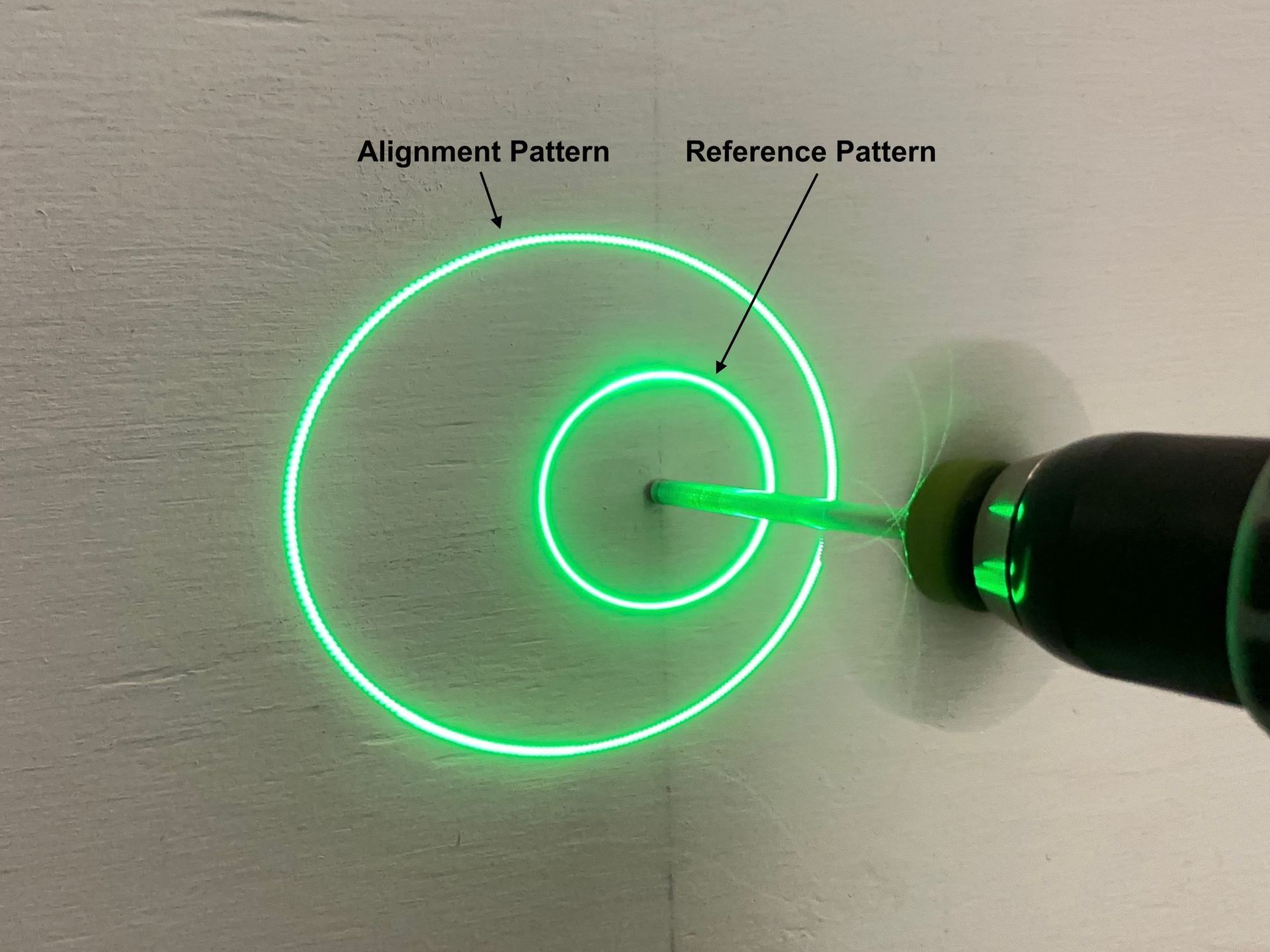

The second beam is known as the Alignment Beam, and this produces a single Alignment Pattern on the work surface while the drill is rotating. Much like the Reference Pattern, the Alignment Pattern is essentially circular when the drill is aligned with a flat work surface, but unlike the Reference Pattern, the Alignment Pattern will distort into an elliptical shape when the drill is misaligned (tilted) with regards to a flat work surface.

Aligned

Misaligned Left

The projection of these two patterns makes the work surface alignment process very simple and quick: when the Alignment Pattern and Reference Pattern are concentric, the drill is aligned perpendicularly with a flat work surface (as shown above). Conversely, if the Alignment Pattern and Reference Pattern are non-concentric and the Alignment Pattern is elliptical, then the drill is misaligned with reference to a flat work surface (as shown on the left).The patterns produced by BullseyeBore Core simply capitalizes on the brain’s ability to visually evaluate circular shapes and concentricity very quickly, and thus provides drill users with the ability to also interpret drill alignment or misalignment rapidly.

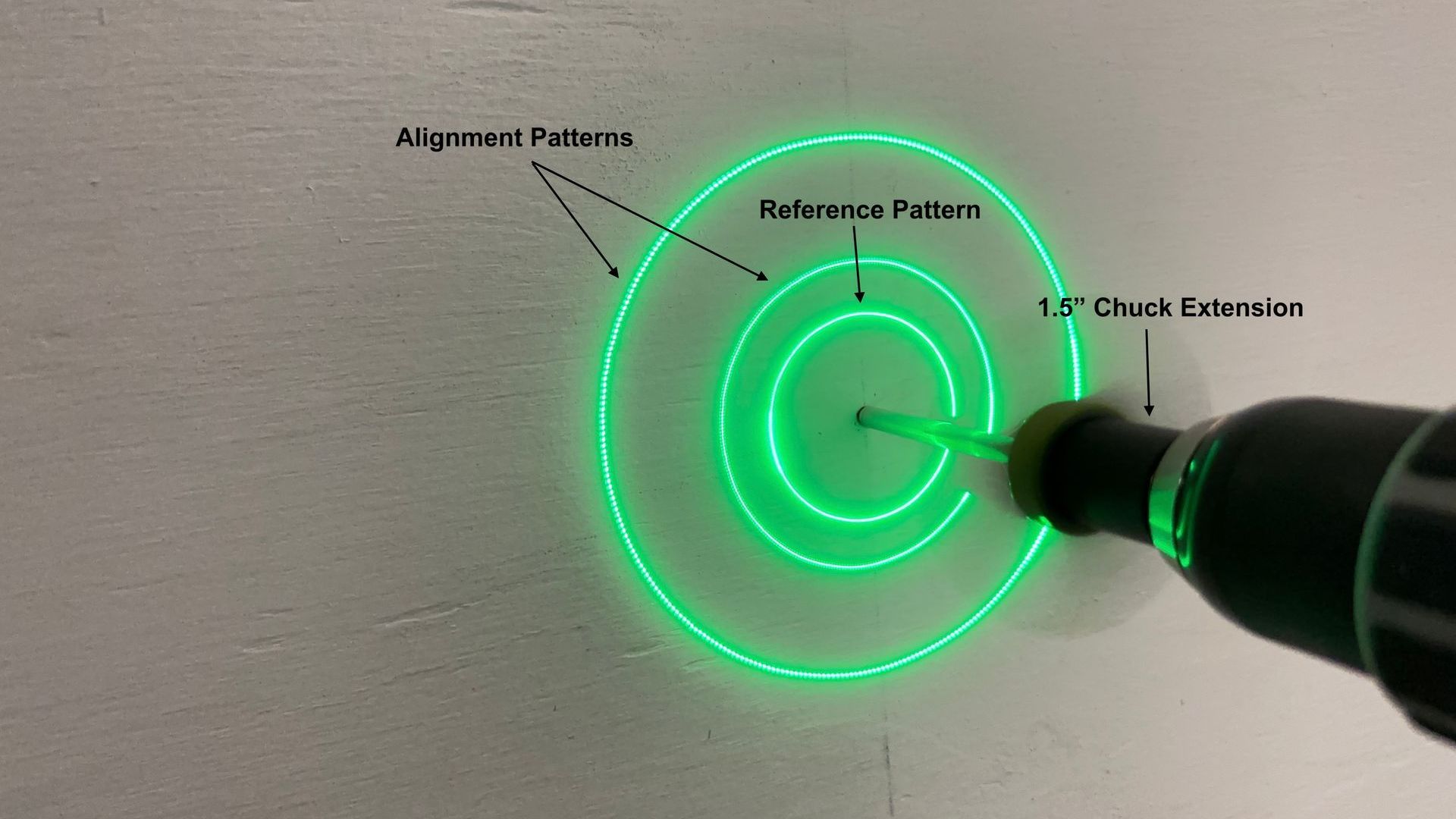

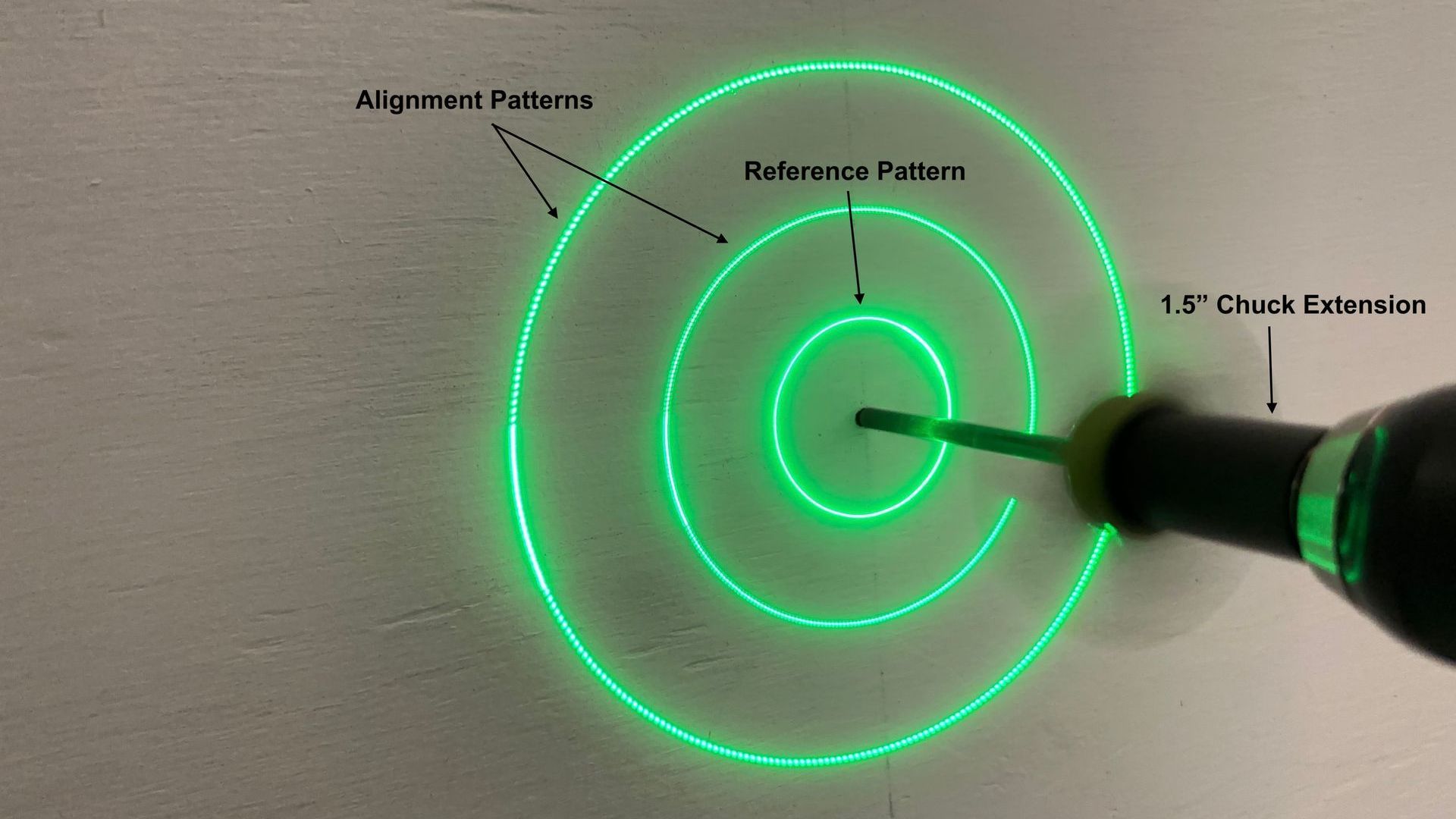

The extended versions of BullseyeBore Core (CR1-101and CG1-101) introduce a second Alignment Pattern. In these extended versions the first and second Alignment Patterns are projected at slightly different angles which translate into different diameters on the work surface and thus work with a wider array of drill bit lengths.

Aligned

Misaligned Left

❸ What are the BullseyeBore Core version differences?

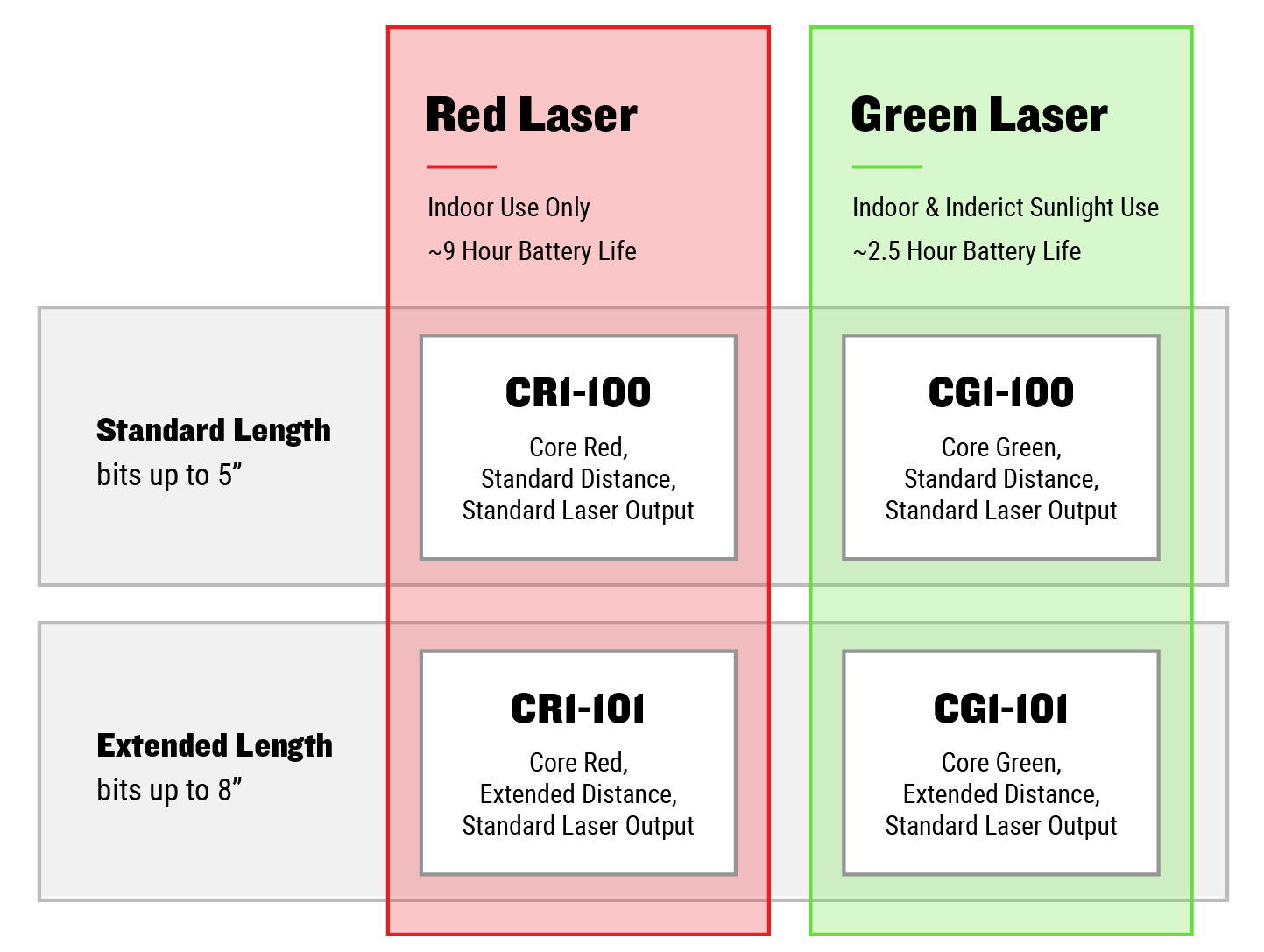

There are four versions (models) of BullseyeBore Core with different characteristics for laser color, battery life, and operational drilling range.

Laser Color Versus Battery Life

The Core Red versions CR1-100 and CR1-101 utilize a red laser and the Core Green versions CG1-100 and CG1-101 utilize a green laser. The Core Red versions use less power than the Core Green (green laser) versions and thus offer better battery life. Conversely, the Core Green versions use a 520nm green laser that is in the middle of the visual frequency spectrum and generally easier to see in bright conditions versus the Core Red versions. The trade-off between the two laser colors is battery life versus visibility.

As a general guide, if you plan to use BullseyeBore Core indoors and battery life is important, select the Core Red versions CR1-100 and CR1-101. Conversely, if you intend to use BullseyeBore Core in bright indoor conditions or indirect sunlight, choose the Core Green versions CG1-100 and CG1-101.

As with all drilling applications, some confined and safe testing should be done first in the expected environmental conditions to assess both work surface pattern visibility and overall safety.

Operational Drilling Range

The standard versions of BullseyeBore Core (CR1-100 and CG1-100) project a single Reference Pattern and a single Alignment Pattern on the work surface and are designed for an operational drilling range of 2” to 5”.This represents the length of most standard commercial drill bits.

The extended versions of BullseyeBore Core (CR1-101 or CG1-101) introduce a second Alignment Pattern for a total of one Reference Pattern and two Alignment Patterns. The two Alignment Patterns are projected at different diameters on the work surface and are designed for operational drilling range of 2” to 8”. The Alignment Patterns also provide more flexibility when using specialty drill bits such as Spade, Augur, Aircraft, Step, or Forstner bits.

As a general guide, if you plan to use BullseyeBore Core with standard length drill bits in the range of 2” to 5”, select from the standard versions of BullseyeBore Core (CR1-100 and CG1-100). Conversely, if you intend to use BullseyeBore Core with a wider variety of drill bit lengths in the 2” to 8” range, or you plan to use specialty bits such as Spade, Augur, Aircraft, Step, or Forstner bits, select from the extended versions of BullseyeBore Core (CR1-101 or CG1-101). The quick BullseyeBore Core version matrix below provides a helpful version selection guide:

❹

Drill compatibility – will BullseyeBore Core work with my drill?

4.1 Drill Compatibility Overview

BullseyeBore Core and the accessories were designed with the goal of working with most common standard electric drills and drill chucks, but due to the vast number of drill and chuck combinations, some careful user testing is required prior to use. Always read and follow the BullseyeBore Core Safety Guidelines before attempting to use BullseyeBore Core or any BullseyeBore Core accessories on a drill or in an actual drilling operation.

As a general guide for drill compatibility, BullseyeBore Core will work with most common commercial electric drills that meet the following conditions:

- The drill chuck face is metallic and flat. The “chuck face” is the very front of the chuck.

- The drill chuck is a common keyed, keyless, or a standard ¼” hex shank chuck.

- The drill chuck has a bit hole of less than or equal to 0.56" diameter.

- The maximum drill RPM is equal to or less than 2500 RPM. The minimum RPM is ~500 RPM.

Depending on the chuck face dimensions and size, an optional Standard Chuck Alignment Guide may be required to prevent displacement of BullseyeBore Core across the chuck face or detachment during rotation. This portion of the FAQ includes additional details on compatibility with Keyed, Keyless and Hex Shank chucks. Please read the applicable sections below:

For more information, please refer to the BullseyeBore Core Product and Accessory Compatibility Guide in the BullseyeBore Core product page

Always read and follow the BullseyeBore Core Safety Guidelines before attempting to use BullseyeBore Core or any BullseyeBore Core accessories on a drill or in an actual drilling operation.

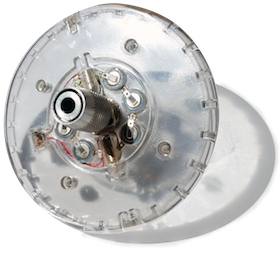

4.2 How does BullseyeBore Core connect to the drill chuck?

The BullseyeBore Core product connects directly to the “chuck face” through a unique patent pending magnetic connection.The “chuck face” is the forward-most portion that the drill bit goes into.

4.3 Will my keyed or keyless drill chuck work with BullseyeBore Core?

Please note that there are tens of thousands of power drills and drill chucks in use worldwide today, and the BullseyeBore team cannot possibly test all of them. Therefore, we have provided some general guidelines below. If you have a hex shank chuck, please see the Will my hex shank chuck with with BullseyeBore Core FAQ below as well.

BullseyeBore Core is designed to work with a wide variety of common 0.375” (3/8”) or 0.5” (1/2") chucks that are used on common commercial electric drills. These two chuck sizes comprise most commercially available chucks in the US and EU. There are generally two criteria that you can use to assess before attempting to use the BullseyeBore Core product with your keyed or keyless drill chuck:

1. The chuck must have a metallic and flat chuck face that is 0.65” or larger.

Your keyed or keyless drill chuck must have a flat metallic chuck face.The chuck face is the forward-most portion that the drill bit goes into. The flat chuck face is typically round in shape with a hole in the center for the drill bit. This hole contains the chuck jaws. BullseyeBore connects directly to the flat chuck face through a unique patent pending magnetic connection. For this to work properly, the chuck face must contain a large enough flat metallic surface to magnetically connect to BullseyeBore Core. Asa general guide, the outer diameter of the flat chuck face must be 0.65” or larger.

2. The flat chuck face hole must be equal to or less than 0.56.”

The keyed or keyless chuck face hole must be equal to or less than 0.56” If the chuck face hole is larger than 0.56", then the extended chuck jaws can interfere with the connection between the face of the chuck and BullseyeBore Core. The use of keyed or keyless chucks with a chuck face hole larger that 0.56” is unsafe and must be avoided.

Please always test the fit and connection of the BullseyeBore Core product on your drill’s chuck face prior to any operations. Some chucks may require installation of an optional Chuck Alignment Guide. This is especially true with smaller keyed or keyless drill chucks such as 0.375” (3/8”) that are typical with smaller power drills. Always read and follow the BullseyeBore Core Safety Guidelines before attempting to use BullseyeBore Core or any BullseyeBore Core accessories on a drill or in an actual drilling operation.

For more information about compatibility, please refer to the BullseyeBore Core Product and Accessory Compatibility Guide in the BullseyeBore Core product page.

4.4

Will my hex shank drill chuck work with BullseyeBore Core?

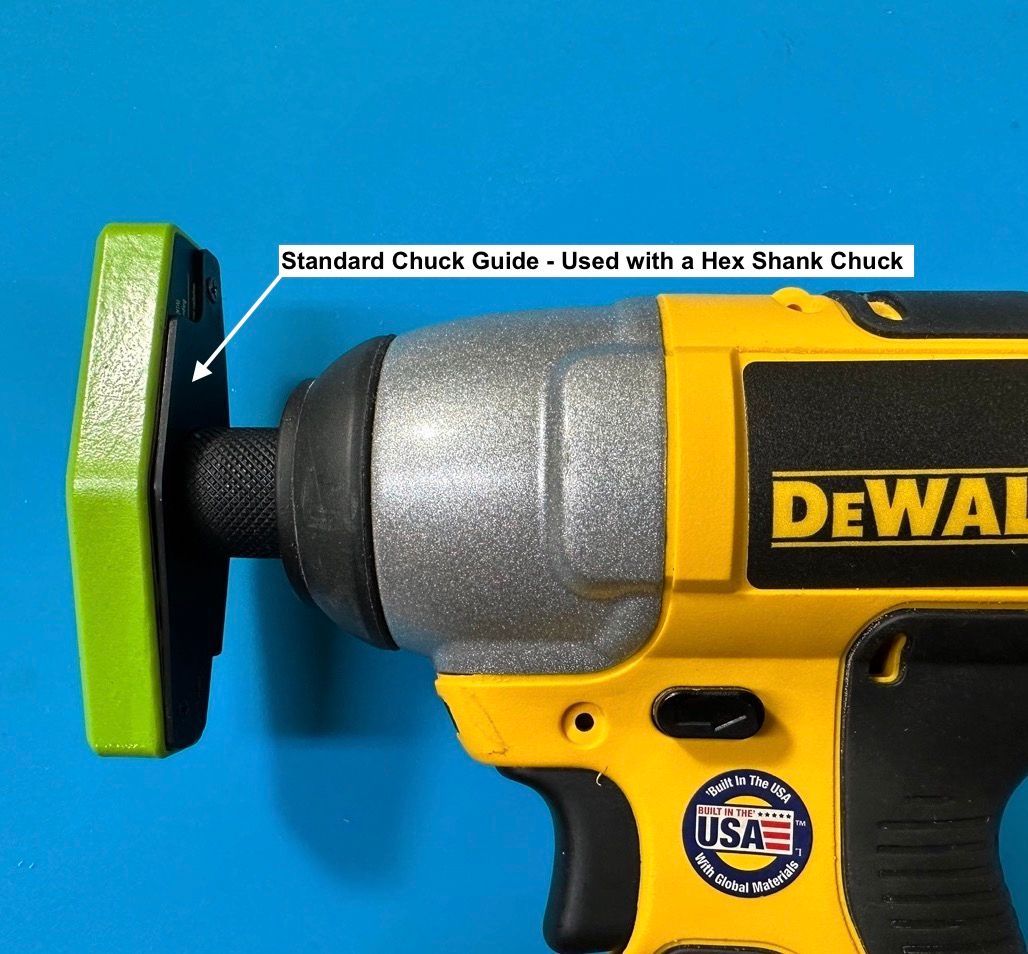

Please note that there are tens of thousands of power drills and drill chucks in use worldwide today, and the BullseyeBore team cannot possibly test all of them. This includes the hex shank drill chucks that are typically common on impact drivers. Therefore, we have provided some general guidelines below.

The BullseyeBore Core product is designed to work with a wide variety of common 0.25” (1/4”) hex shank chucks. There are generally two criteria that you can use to assess if the Core product will work with your hex shank chuck

1.The hex shank drill chuck must have a metallic flat face that is 0.44” or larger.

Your hex shank drill chuck must have a metallic flat face. The “face” of the chuck is the forward-most portion that the bit goes into. The face is typically round with a hex shaped hole in the center that locks the hex bit in place. BullseyeBore Core connects directly to the face of the hex chuck through a unique patent pending magnetic connection. The face must contain a large enough flat metallic surface to magnetically connect to BullseyeBore Core. As a general guide, the outer diameter of the metallic flat hex chuck face must be 0.4” or larger.

2.The hex shank drill chuck bit hole must be the standard 0.25” (1/4”) hex hole.

Standard hex shank drill chuck bit holes are typically slightly larger than0.25” (1/4”). Do not use BullseyeBore Core with non-standard hex shank chucks.Here is an image of standard hex shank bits and anassociated hex shank drill chuck.

Please always test the fit and connection of the BullseyeBore Core product on your chuck face prior to any operations. Most standard hex chucks require installation of an optional Standard Chuck Alignment Guide. Always read and follow the BullseyeBore Core Safety Guidelines before attempting to use BullseyeBore Core or any BullseyeBore Core accessories in an actual drilling operation.

For more information about compatibility, please refer to the BullseyeBore Core Product and Accessory Compatibility Guide in the BullseyeBore Core product page.

4.5 Can I use BullseyeBore Core with a standard pneumatic drill?

Yes, in most cases BullseyeBore Core works with pneumatic drills. However, this is ultimately dependent on the characteristics of the drill and drill chuck. Please see the FAQs titled Drill Compatibility Overview and Will my keyed or keyless drill chuck work with BullseyeBore Core? for guidance and limitations.

Please also note that many pneumatic drills have a maximum RPM that exceeds the 2500 RPM limitation of BullseyeBore Core. Further, pneumatic drills can accelerate much fast than commercial electric drills, so a Standard Chuck Alignment Guide is typically recommended.

Please always test the fit and connection of the BullseyeBore Core product on your chuck face prior to any operations. Always read and follow the BullseyeBore Core Safety Guidelines before attempting to use BullseyeBore Core or any BullseyeBore Core accessories on a drill or in an actual drilling operation.

4.6

Can I use BullseyeBore Core with a standard electric hammer drill?

Some commercial electric drills have a separate hammer drill setting. This FAQ answer is in reference to those types of drills only. If you intend to use a rotary hammer drill, please see the rotary hammer drill FAQ below.

Although it is possible to use BullseyeBore Core with a standard electric drill in the hammer drill setting, it is not recommended for two reasons. First, BullseyeBore Core is not designed for extended use with a hammer drill. Such use will shorten the life of the product dramatically. Use with a hammer drill is also not covered under any BullseyeBore Core product warranty. Second, the hammering thrust of some hammer drills can induce rhythmic waves in the patterns on the work surface. Please see the FAQ titled What causes projected laser pattern vibration?

If you are interested in a dedicated version of BullseyeBore Core that is designed for use with a standard electric hammer drill, please contact us.

4.7 Can I use BullseyeBore Core with a rotary hammer drill?

No, rotary hammer drills do not have the metallic flat chuck face required and thus cannot be used with BullseyeBore Core. Rotary hammer drills typically have a plastic or rubber chuck and/or chuck face that is non-metallic. Do not attempt to use BullseyeBore Core with a rotary hammer drill.

4.8 What specific drills is BullseyeBore Core

incompatible with?

BullseyeBore Core Products and accessories will NOT work with the following drills or chucks. Do not use BullseyeBore Core and accessories on drills with any of these characteristics:

- Drills with a chuck face that is non-metallic and/or not flat. The “chuck face” is the very front of the chuck.

- Drills with drill chucks that have a bit hole of greater than 0.56" diameter.

- Drills with a maximum RPM greater than 2500 RPM.

- Rotary Hammer Drills.

- Drills with small chucks such as a 1/4" chuck.

Always read and follow the BullseyeBore Core Safety Guidelines before attempting to use BullseyeBore Core or any BullseyeBore Core accessories on a drill or in an actual drilling operation.

❺ Drill bit compatibility – will BullseyeBore Core work with my drill bits?

5.1 What is the maximum drill bit diameter supported by BullseyeBore Core?

BullseyeBore Core supports common drill bits with a

shaft diameter of up to and including 0.5” (1/2”).

5.2 What is the drill bit length range supported by BullseyeBore Core?

In general, the BullseyeBore Core products are designed for drill bit lengths from 2.0” to 8.0”. While longer drill bits can be used, the resulting Alignment Pattern (or Patterns) on the work surface may be too far from the Reference Pattern for use. A common solution for longer bits is the integration of a Chuck Extension, which is designed to reduce the Alignment Pattern size with longer drill bits. Moreover, if the work surface area is small, integration of a Work surface Extension Plate may also assist with pattern visualization. See the FAQ for

Can the extended versions of BullseyeBore Core operate with drill bits longer than 8”? for more information on BullseyeBore Core and drill bits longer than 8”.

5.3 Which BullseyeBore Core version should I use with standard length bits or longer bits?

The standard versions of BullseyeBore Core (CR1-100 and CG1-100) project a single Reference Pattern and a single Alignment Pattern on the work surface and are designed for an operational drilling range of 2”to 5”. This represents the length of most standard drill bits.

The extended versions of BullseyeBore Core (CR1-101 or CG1-101) introduce a second Alignment Pattern for a total of one Reference Pattern and two Alignment Patterns. The two Alignment Patterns are projected at different diameters on the work surface and are designed for an operational drilling range of 2” to 8”. The Alignment Patterns also provide more flexibility when using specialty drill bits such as spade, aircraft, step, or hex bits.

As a general guide, if you plan to use BullseyeBore Core with standard length drill bits in the range of 2” to 5”, select from the standard versions of BullseyeBore Core (CR1-100 and CG1-100). Conversely, if you intend to use BullseyeBore Core with a wider variety of drill bit lengths in the 2” to 8” range, or you plan to use specialty bits such as Spade, Aircraft, Step, Hex, or Forstner, select from the extended versions of BullseyeBore Core (CR1-101 or CG1-101).

5.4 Can the extended versions of BullseyeBore Core operate with drill bits longer than 8"?

Yes, the extended versions of BullseyeBore Core (CR1-101 or CG1-101) have been successfully tested with drill bits longer than 8”. However, the diameter of the Alignment Patterns is proportional to the length of the bit, so longer bits produce larger Alignment Patterns on the work surface. This means that 1) the work surface must be large enough to support all or some portion of the Alignment Patterns, and 2) the inner most Alignment Pattern must be close enough to the Reference Pattern to utilize. If the inner most Alignment Pattern is too far from the fixed Reference Pattern, concentricity can be difficult to visualize. A common solution to this problem is integration of a Chuck Extension, which is designed to reduce the Alignment Pattern size with longer drill bits so that it is closer to the fixed Reference Pattern. See the FAQ section for

Chuck Extensions for more information.

5.5 Does BullseyeBore Core work with specialty drill bits such as Spade, Step, Augur, Forstner, Hex shank, or Aircraft bits?

The extended versions of BullseyeBore Core (CR1-101 or CG1-101) have been successfully tested with a wide variety of specialty bits such as Hex Shank, Spade, Augur, Step, Forstner, and Aircraft bits in different sizes and lengths. However, BullseyeBore Inc. cannot guarantee compatibility with any specific specialty drill or cutting bit. There are tens of thousands of specialty bits in use worldwide today, and the BullseyeBore team cannot possibly test all of them.

As general guidance, all specialty bits used with BullseyeBore Core must incorporate a chuck mounting shaft with a maximum diameter of 0.5” and a cutting tool head of 1” or less. BullseyeBore Core cannot support any bit or bit shaft that is larger than 0.5”, or any cutting tool head larger than 1”. It is also possible that some specialty bits that fall within these acceptable criteria may not work with BullseyeBore Core.

Moreover, larger diameter drill bits or specialty bits with larger cutting diameters can introduce work surface vibration or vibration of the bit in the bore hole that translates into the projected patterns. See the FAQ for What causes projected laser pattern Vibration?

Always read and follow the BullseyeBore Core Safety Guidelines before attempting to use BullseyeBore Core or any BullseyeBore Core accessories on a drill or in an actual drilling operation.

Here is a general guide for specific specialty bits:

Hex Shank Bits

The standard versions of BullseyeBore Core (CR1-100 or CG1-100) and extended versions of BullseyeBore Core (CR1-101 or CG1-101) have been tested with a wide variety of standard Hex Shank bits with a ¼” hex shank. Moreover, some hex shank drill chucks that are typically common on impact drivers have been successfully tested with BullseyeBore Core. Please see the FAQ titled: Will my hex shank drill chuck work with BullseyeBore Core?

Spade Bits

Spade bits with cutting heads of up to 1.0” cutting diameter have been successfully tested with the extended versions of BullseyeBore Core (CR1-101 or CG1-101).The Spade bit chuck mounting shaft must have a maximum diameter of 0.5”, and there must be enough room on the mounted shaft for BullseyeBore Core to securely attach to the chuck face. Since Spade bits tend to be longer, use of a Chuck Extension is recommended. A Chuck Extension is designed to reduce the Alignment Pattern size with longer drill bits.

0.5" Spade Bit Usage video

Spade bits with a cutting diameter of 0.5" should be attached and secured in the drill chuck prior to installation of BullseyeBore Core and/or an optional BullseyeBore Chuck Extension.

Larger Spade Bit Attachment video

If the Spade bit has a cutting diameter larger than 0.5", the attachment process requires BullseyeBore Core (and the optional Chuck Extension) to be mounted on the drill prior to the Spade bit. The video below contains an example with a 0.75" Spade bit, and the procedure is outlined in the FAQ Does BullseyeBore Core require removal for a drill bit change?

Augur Bits

Augur bits of up to 1.0” cutting diameter have been successfully tested with the extended versions of BullseyeBore Core (CR1-101 or CG1-101).The Augur bit chuck mounting shaft must have a maximum diameter of 0.5”, and there must be enough length on the mounted shaft for BullseyeBore Core to securely attach to the chuck face. Since Augur bits tend to be longer, use of an optional

BullseyeBore Core Chuck Extension is recommended. A Chuck Extension is designed to reduce the Alignment Pattern size with longer drill bits. If the Augur bit cutting diameter is larger than 0.5”, the attachment process also requires BullseyeBore Core to be mounted on the drill prior to the Augur bit (just like the larger Spade bit attachment process outlined above).

Step Bits

Step bits of up to 1.0” cutting diameter have been successfully tested with the extended versions of BullseyeBore Core (CR1-101or CG1-101). The Step bit chuck mounting shaft must have a maximum diameter of 0.5”, and there must be enough length on the mounted shaft for BullseyeBore Core to securely attach to the chuck face.

Depending on the diameter of the Step bit, the mounting position of BullseyeBore Core on the chuck may need to be rotated so that one or more of the projected Alignment Beams can clear the angled Step bit diameter. Moreover, one or more of the projected Alignment Beams may simply be blocked by the Step bit no matter what rotational mounting position of BullseyeBore Core on the chuck is implemented.

If the Step bit cutting diameter is larger than 0.5”, the attachment process also requires BullseyeBore Core to be mounted on the drill prior to the Step bit (just like the larger Spade bit attachment process outlined above).

Forstner Bits

Forstner bits of up to 1.0” cutting diameter have been successfully tested with the extended versions of BullseyeBore Core (CR1-101 or CG1-101). The Forstner bit chuck mounting shaft must have a maximum diameter of 0.5”, and there must be enough room on the mounted shaft for BullseyeBore Core to securely attach to the chuck face. Further, if the Forstner bit cutting diameter is larger than 0.5”, the attachment process also requires BullseyeBore Core to be mounted on the drill prior to the Forstner bit (just like the Spade bit attachment process outlined above).

5.6 What specialty drill bits are

incompatible with BullseyeBore Core?

As general guidance, all specialty bits used with BullseyeBore Core must incorporate a chuck mounting shaft with a maximum diameter of 0.5” and a cutting tool head of 1” or less. BullseyeBore Core cannot support any bit or bit shaft that is larger than 0.5”, or any cutting tool head larger than 1”. It is also possible that some specialty bits that fall within these acceptable criteria may not work with BullseyeBore Core.

Please see the type or types below for specific specialty drill bits that are incompatible with BullseyeBore Core.

Hole Saw

Hole Saw bits do not operate with BullseyeBore Core because the hole saw diameter typically blocks the projected beams. However, the BullseyeBore team has designed a unique prototype version of BullseyeBore Core specifically for hole saw bits. We may consider this as a specialty product in the future. Please

contact us if you are interested.

❻ BullseyeBore Core General FAQ

6.1 What safety guidelines should I follow before, during, and after BullseyeBore Core use?

Always read and follow the BullseyeBore Core Safety Guidelines before attempting to use BullseyeBore Core or any BullseyeBore Core accessories on a drill or in an actual drilling operation. Although BullseyeBore Core and the BullseyeBore Core accessories are designed with safety in mind, power tools such as drills are dangerous, and accidents can occur if they are not used properly. Please also read this complete FAQ to familiarize yourself with the BullseyeBore Core product and accessories before use.

6.2 Does BullseyeBore Core work in any orientation?

Yes, BullseyeBore Core works in any orientation and is designed to operate with any type of flat or gently curved work surface. This work surface can be a wall, floor, ceiling, wing, fuselage, or other surface positioned in any orientation.

6.3 Are the Worksurface Patterns Visible through BullseyeBore rotation?

Yes, the worksurface patterns produced by BullseyeBore when viewed through BullseyeBore rotation are visible. However, the patterns may be partially obstructed when the front of BullseyeBore comes within one inch of the work surface. Moreover, the rotational speed of the drill can impact worksurface pattern visibility, especially when the front of BullseyeBore comes within one inch of the worksurface. The best way to avoid any work surface pattern obstruction is to position your view above, below, or to the side of the drill and not directly behind it. Alternatively, you can simply use a longer drill bit for the given drilling operation.

Caution should also be exercised when drilling vertically into a ceiling or similar structure. If you are positioned below the drill, and the ceiling or structure can generate a lot of debris during drilling, the debris can fully or partially obstruct the BullseyeBore Core optical window and thus block the laser projections on the work surface. For example, drilling into a drywalled ceiling can generate a lot of dust and debris and obstruct the BullseyeBore Core optical window.

As a general guide, if you plan to use BullseyeBore Core indoors and battery life is important, select the Core Red versions CR1-100 and CR1-101. Conversely, if you intend to use BullseyeBore Core in bright indoor conditions or indirect sunlight, choose the Core Green versions CG1-100 and CG1-101.

6.4 Does BullseyeBore Core need to be centered on the chuck face for proper use?

No, BullseyeBore Core does NOT need to be centered on the chuck face for work surface alignment drilling operations. The work surface patterns from BullseyeBore Core are produced from one side of the BullseyeBore Core arm and thus always produce circular patterns when the drill is aligned with the work surface.

However, there are a couple of conditions where centering BullseyeBore Core on the chuck face (e.g., centering BullseyeBore Core on the rotational axis of the drill) is helpful. First, if your drill is small or lightweight, an uncentered BullseyeBore Core can create an “unbalanced” condition during drill rotation and drilling operations. This can lead to some vibration and/or perceived rotational instability. Second, if you want a consistently positioned Reference Pattern on the work surface with the drill bit at the center, then centering BullseyeBore Core on the chuck face is important.

The simplest and best method for consistent centering of BullseyeBore Core on the chuck face is by using a Standard Chuck Alignment Guide. Please see the Standard Chuck Alignment Guide FAQs below for more information, or the Standard Chuck Alignment Guide page.

BullseyeBore Core utilizes low power lasers in the range of 1mW that are certified as Class 1 lasers. Class 1 lasers are eye safe as defined under the US FDA regulations and are thus very low in output power. As a result, none of the current BullseyeBore Core versions will be operationally visible in DIRECT sunlight. However, the Core Green versions are designed to be operationally visible in INDIRECT sunlight or in bright indoor conditions. If you intend to use BullseyeBore Core in bright indoor conditions or indirect sunlight, choose the Core Green versions CG1-100 and CG1-101.

As with all drilling applications, some testing should be done first in the expected environmental and visibility conditions to assess both worksurface pattern visibility and overall safety.

6.6 Does BullseyeBore Core require removal for a drill bit change?

BullseyeBore Core does not require removal for a drill bit change, but it is advised to do so whenever possible so that the drill bit can be fully engaged and secured into the chuck jaw teeth and verified prior to BullseyeBore Core attachment and drilling operations. However, when using a Spade, Auger, Forstner, or Step bit whose cutting diameter is larger than 0.5”, BullseyeBore should be securely attached to the chuck before attachment of the drill bit. In this case its best to:

- Open the chuck jaws wide enough to support the drill bit shaft.

- Securely attach BullseyeBore Core to the chuck and insert the bit.

- Fully engage and secure the drill bit shaft into the chuck jaw teeth.

- Verify that the chuck jaw teeth are fully engaged with the drill bit shaft prior to drilling operations.

- Perform a low RPM test to make sure that the BullseyeBore Core is securely attached to the chuck face and the drill bit shaft is fully engaged as well as rotationally centered and secured in the drill chuck jaw teeth.

6.7 Does BullseyeBore Core work on curved worksurfaces?

Yes, BullseyeBore Core can be used for worksurface alignment on both flat and curved worksurfaces. In the case of constant curved worksurfaces, the Reference Pattern and Alignment Pattern or Patterns will be slightly elliptical in the direction of the constant curved worksurface but can still be compared to determine worksurface alignment versus misalignment.

BullseyeBore Core can potentially also operate on worksurfaces with gentle compound curves but may require some experimentation or test drilling first for optimal alignment.

6.8 How accurate are drill holes with BullseyeBore Core?

Drilling accuracy is defined as the angle of a drill hole with regards to the plane of the worksurface. A perfectly drilled hole will be perpendicular to its worksurface. This is what we refer to as a “straight hole”.

The ability to drill a straight hole will depend on several criteria including the quality of both the drill and drill bits, the worksurface material, as well as the drill operator’s ability to properly use the drill. Of course, it will also depend on the drill operator’s ability to correctly install and utilize BullseyeBore Core on the drill during the drilling operation.

Since “skills and drills” vary, BullseyeBore Core alone cannot ensure that everybody can rise to Pro level, but we’ve found that an average DIY can typically drill with an error rate on a flat wooden worksurface of less than ±1 degrees after just 10-20 minutes of initial BullseyeBore Core use. Moreover, we’ve found that experienced DIY users can typically achieve an error rate of under ±0.5 degrees with BullseyeBore Core when used on a regular basis. That equates to a drill hole that is between 89.5° and 90.5° accurate in both the X & Y directions (with 90° as perfect).

6.9 Is BullseyeBore Core waterproof?

No, BullseyeBore Core is not designed to be waterproof or water resistant. Please avoid direct exposure to water or immersion. If you are interested in a version of BullseyeBore Core that is water resistant or waterproof, please contact us.

6.10 Is BullseyeBore Core resistant to chemicals or drill lubricants?

No, BullseyeBore Core is not designed to be chemical or drill lubricant resistant. Please avoid direct exposure to chemical or drill lubricants.

6.11 Can I still use BullseyeBore Core for drill alignment if only a portion of the patterns are visible on the work surface?

Yes, typically as long as 50% of the Reference Pattern and 50% of at least one of the corresponding Alignment Patterns are visible, BullseyeBore Core can be used for drill alignment. This can occur when drilling near the edge of a worksurface or near the corner of a worksurface. Here is a video that demonstrates edge drilling.

6.12 What can I do if the worksurface pattern is too large for the worksurface?

You may encounter drilling scenarios where less than 50% of the Reference Pattern and the corresponding Alignment Pattern are visible on the worksurface. This can occur if you are drilling on a small worksurface such as on the edge of a 2x4. The best approach in this case is to use a BullseyeBore Worksurface Extension Plate. A BullseyeBore Worksurface Extension Plate is a flat aluminum circular plate that can be held in place on the flat worksurface to “extend” it so the worksurface patterns are fully visible. Further, if the entire length of drill bit is not required for the drilling operation, an optional Chuck Extension accessory may be incorporated to reduce the Alignment Pattern size at the start of drilling.

6.13 What causes projected laser pattern vibration?

Drill Bit Induced Worksurface Laser Pattern Vibration

Drill bit vibration or “chatter” can occur with any drill bits but is most common with larger diameter drill bits as well as specialty bits with larger cutting diameters. Drill bit vibration typically happens when the drill bit begins cutting or when it vibrates within a drill hole during cutting. In both situations the resulting bit vibration can be translated into the BullseyeBore Core projected patterns. This may appear as rhythmic waves in the laser patterns on the worksurface, and their appearance indicates that there is something wrong in the drilling operation.

In this situation, BullseyeBore Core helps you to visualize the problem. When you see these rhythmic waves in the laser patterns, its a good indication that you need to invoke better drill control, use sharper drill bits, modify your feed rate, and/or stabilize the workpiece that you are drilling into (more on this below).

Here is an example of drill bit vibration with a large 0.5” diameter bit that occurred at the start of drilling. This is caused by the combination of a large diameter bit and a poorly stabilized workpiece. In this case the vibration subsides as the hole is formed.

Here is an example of drill bit vibration caused by the combination of a dull spade bit with a poorly stabilized workpiece. Note that the vibration starts when the drill bit hole is formed and increases as the bit vibrates within the hole. Turn on the audio to hear the drill bit “chatter”.

While wood is generally softer and less prone to chatter or vibration when compared to metals, certain conditions or factors can still contribute to the occurrence of drill bit vibration or chatter in wood drilling operations. Some factors that can cause drill chatter or vibration in wood include:

- Dull or improperly sharpened drill bits: Blunt or improperly sharpened drill bits can cause the drill to grab and vibrate, resulting in chatter.

- Excessive feed rate: Applying too much pressure or feeding the drill too quickly into the wood can cause the bit to vibrate and chatter.

- Inadequate tool rigidity: Using a drill with low rigidity or flexibility can lead to increased vibrations and chatter during wood drilling.

- Incorrect drill point geometry: Using drill bits with incorrect point angles or unsuitable geometries for wood drilling can contribute to chatter.

- Poorly stabilized workpiece: If the workpiece is thin or poorly stabilized, the workpiece itself can vibrate and contributed to chatter.

To minimize drill chatter when drilling in wood, you can consider the following steps:

- Use sharp and properly maintained drill bits specifically designed for wood drilling.

- Control the feed rate by applying steady and moderate pressure while drilling.

- Ensure the drill, drilling setup, and workpiece are stable and rigid to minimize vibrations.

- Consider using a center punch or pilot hole to provide a starting point and guide for the drill bit.

- If possible, use drills with specially designed point geometries for wood drilling, such as brad-point or spade bits.

Hammer Drill Induced Worksurface Laser Pattern Vibration

Worksurface pattern vibration can also occur when BullseyeBore Core is used with common commercial electric hammer drills. Such drills introduce a worksurface hammering motion that is often translated into the BullseyeBore Core projected patterns. This may also appear as rhythmic waves in the laser patterns on the worksurface. This may be somewhat diminished by worksurface stabilization that can dampen the worksurface vibration. In most cases, however, the BullseyeBore Core worksurface patterns with common commercial electric hammer drills are still usable.

6.14 Are the BullseyeBore technologies and products patented?

Yes, all our technologies and products are either patented or patent pending in the US and/or internationally. We believe strongly in our intellectual property rights and will vigorously defend them. Please also be advised that some of our patents pending are not publicly available or published at this time.

6.15 What happened to the original “BullseyeBore Disk” product that was on your website?

Several years ago, we introduced a prototype version of the BullseyeBore intellectual property and technology on our website called the “BullseyeBore Disk”. It was a first attempt at an implementation of the patented BullseyeBore drill alignment and depth technologies.

Our goal for that prototype was two-fold. First, we wanted to assess customer interest and determine if there was a market need. We discovered quickly that we were headed in the right direction. Within a couple months of introduction, the prototype videos had well over a million views (which was a lot for way back then). We also received a lot of positive feedback and suggestions from power drill users all over the world. The BullseyeBore Disk prototype, even in its somewhat bulky form, solved a significant problem for power drill users, which is worksurface alignment.

The second goal for the BullseyeBore Disk prototype was to get in into the hands of actual users for testing and feedback. We wanted to find out how they used it, what features were important, and how it could be improved. This process unfortunately took much longer that we expected.

We discovered during testing that we had to solve five issues:

- How to mount it to any common commercial electric drill or common drill chuck (without the hex shaft-based mount in the prototype),

- how to interoperate with standard drill bits and specialty drill bits (as opposed to the hex-shank-bit-only approach in the prototype),

- how to substantially reduce the laser module size and power requirements,

- how to make the overall product both smaller and ubiquitous during rotation, and

- how to make it super-safe to use.

Over the course of several years, we developed, implemented, and tested well over 300 prototypes. This lengthy R&D process included development of custom low power red and green lasers, creation of custom laser optics, testing of several hundred form factors, and perhaps most critically, development of a universal drill chuck attachment mechanism that emphasized user safety. The chuck attachment mechanism was an extremely difficult design challenge given the wide diversity of drills and chucks, but the solution turned out to be very elegant and has been tested on several hundred different drill and drill chuck combinations.

The result of the years-long development process is the BullseyeBore Core product line. The Core product line is the first of many patented drill and power tool alignment and depth products we plan to offer (yeah–there are a lot more great products on the way).

For those of you that have patiently waited for the first commercial version of the BullseyeBore power drill worksurface alignment product, thanks very much! Our goal has always been to release a great product that allows you to “Always Drill Straight”, and we think you will really like it.

BullseyeBore Core uses two common 357 coin cell batteries. Both batteries are mounted with the negative side pointing down towards the circuit board. We recommend the use of either Energizer 357 or Duracell 357 batteries. Standard LR44 coin cell batteries typically work with BullseyeBore Core, but do not provide as much battery life (durational use) as either Energizer 357 or Duracell 357 batteries.

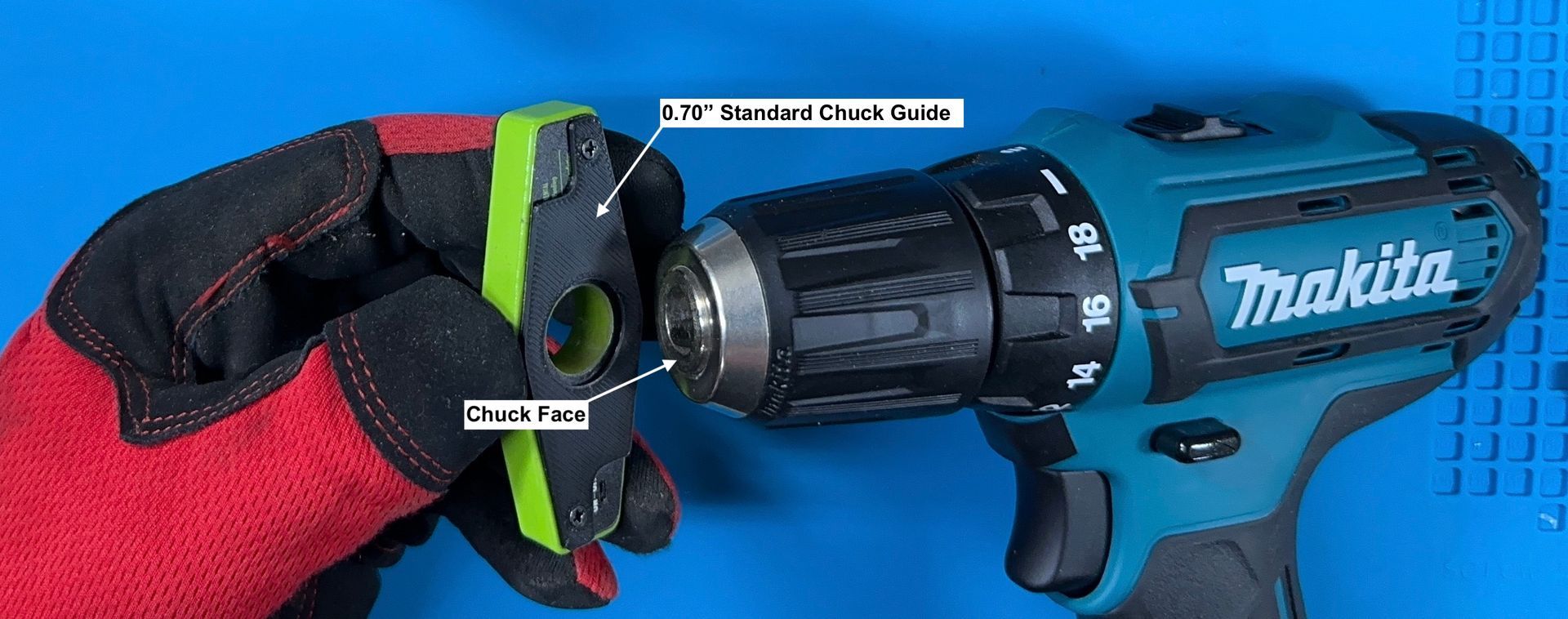

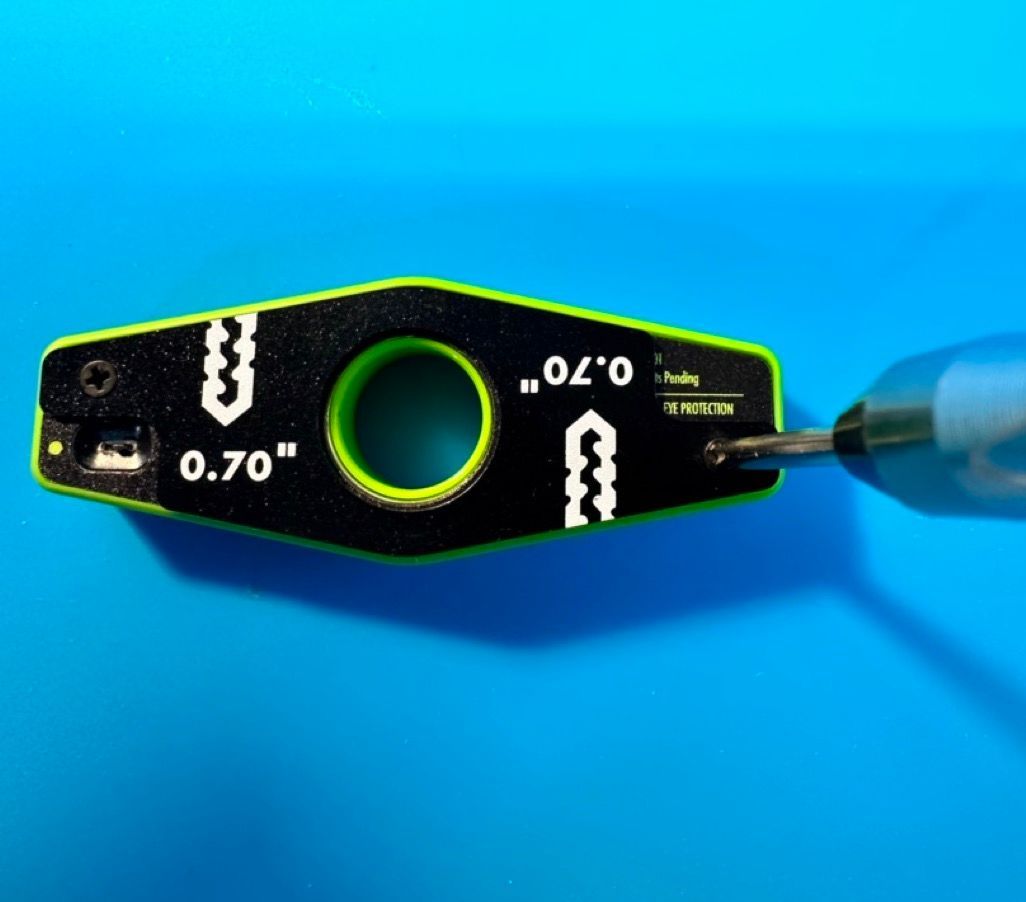

BullseyeBore Core Standard Chuck Alignment Guides are an optional accessory in the BullseyeBore Core accessory ecosystem.

A single Standard Chuck Alignment Guide can be screwed onto the back of the BullseyeBore Core device over the label. Standard Chuck Alignment Guides are designed for two purposes:

- First, they provide a means to consistently center BullseyeBore Core onto the flat chuck face during installation. This makes repeated installations onto the drill chuck face both easy and consistent.

- Second, they help to prevent lateral displacement (sliding) of BullseyeBore Core across the flat chuck face. Lateral displacement can occur during initial drill rotation or high-speed rotation, but is most common during electric breaking (e.g., when your finger is removed from the drill trigger and the drill stops suddenly). Some power drills employ a strong electric breaking function that creates an abrupt stop to any drill rotation.

Standard Chuck Alignment Guides are offered in nine different center hole size options of 0.70”, 0.75”, 0.80”, 0.85”, 0.90”, 0.95”, 1.00”, 1.05” and 1.10”. This range of guides provides for the ability to work with a wide array of drill chuck face diameters.

Most standard 0.5” (1/2") keyed or keyless chucks do not require a Chuck Alignment Guide as there is a large enough flat metallic surface to magnetically hold BullseyeBore Core in place during drilling operations without the threat of lateral displacement (sliding across the flat chuck face). However, there are two cases where a Standard Chuck Alignment Guide can be very helpful:

- First, if you plan to repeatedly mount and dismount BullseyeBore Core on your drill chuck, a Standard Chuck Alignment Guide can be helpful. The Standard Chuck Alignment Guide provides a means to consistently center BullseyeBore Core onto the flat chuck face during installation. Mounting BullseyeBore Core on the center of the flat chuck face during installation leads to better balance and rotational stability during drilling operations.

- Second, if you have a drill with a small chuck or a hex shank bit chuck, a Standard Chuck Alignment Guide can be helpful. Lateral displacement (sliding slightly across the flat chuck face) can occur with smaller chucks such as standard 0.375” (3/8”) keyed or keyless chucks or standard 0.25” (1/4”) hex shank chucks during drilling or electric breaking.

The use of a Standard Chuck Alignment Guide typically prevents both issues and is recommended. Standard Chuck Alignment Guides are inexpensive, and we always recommended purchasing at least one set to carry and optionally use with BullseyeBore Core.

Standard Chuck Alignment Guides are offered in nine different center hole size options of 0.70”, 0.75”, 0.80”, 0.85”, 0.90”, 0.95”, 1.00”, 1.05” and 1.10”. This range of guides provides for the ability to work with a wide array of drill chuck face diameters.

The best way to choose the correct chuck guide is to first measure the round diameter of your drill’s flat chuck face that BullseyeBore magnetically connects to, and then to select the Chuck Alignment Guide whose center hole diameter is slighter larger than your chuck face. After installation of the chuck guide and mounting onto the drill chuck, BullseyeBore Core should seat flatly and securely against your drill’s flat chuck face, but you should also be able to manually slide BullseyeBore Core very slightly (perhaps 1/10th of an inch or less) from side to side across the chuck face. The most important requirement is for BullseyeBore Core to seat firmly and completely against the chuck face. The Chuck Alignment Guide should NOT interfere with this seating.

Please also note that most standard 0.5” (1/2") keyed or keyless chucks do not require a Chuck Alignment Guide as there is a large enough flat metallic surface to magnetically hold BullseyeBore Core in place during operations without the threat of lateral displacement (sliding across the flat chuck face). The large chuck jaws standard 0.5” (1/2") keyed or keyless chucks typically also extend out of the drill bit hole and provide additional prevention of lateral displacement (sliding slightly across the flat chuck face).

After you have selected the proper size Chuck Alignment Guide using the instructions above, remove the two screws from the back (label side) of BullseyeBore Core. Then overlay and center the proper size Chuck Alignment Guide onto the BullseyeBore Core label and replace the two screws. The Standard Chuck Alignment Guide contain angled fillet screw head slots for the screw heads to fit into so they are flush with the Standard Chuck Alignment Guide after the screws are installed.

Always read and follow the BullseyeBore Core Safety Guidelines before attempting to use BullseyeBore Core or any BullseyeBore Core accessories on a drill or in an actual drilling operation. When using Standard Chuck Alignment Guides, please also ensure that BullseyeBore Core is securely connected to the “face” of the chuck.

9.1 What are Chuck Extensions and what are they used for?

BullseyeBore Core Chuck Extensions are an optional accessory in the BullseyeBore Core ecosystem that fits between the drill chuck face and the back of BullseyeBore Core.

Chuck Extensions serve to move BullseyeBore Core forward along the drill bit and are typically utilized to move BullseyeBore Core’s projected Reference and Alignment Patterns closer together on the worksurface at the start of drilling, which can make drill alignment or misalignment easier to visualize. They can also be used to reduce the overall diameter of the Alignment Pattern (or Patterns) if they do not fit on the worksurface.

The example below depicts a 5.75” drill bit and the resulting patterns at the start of drilling both with and without a Chuck Extension.

Core Green Extended with a 5.75” bit without a Chuck Extension

Core Green Extended with a 5.75” bit and a 1” Chuck Extension.

Note how the Fixed Reference Pattern and Alignment Patterns are closer for easier alignment or misalignment interpretation.

The example below depicts a 7” drill bit and the resulting patterns at the start of drilling both with and without a Chuck Extension.

Core Green Extended with a 7” bit without a Chuck Extension

Core Green Extended with a 7” bit and a 1.5” Chuck Extension.

Note how the Fixed Reference Pattern and Alignment Patterns are closer for easier alignment or misalignment interpretation.

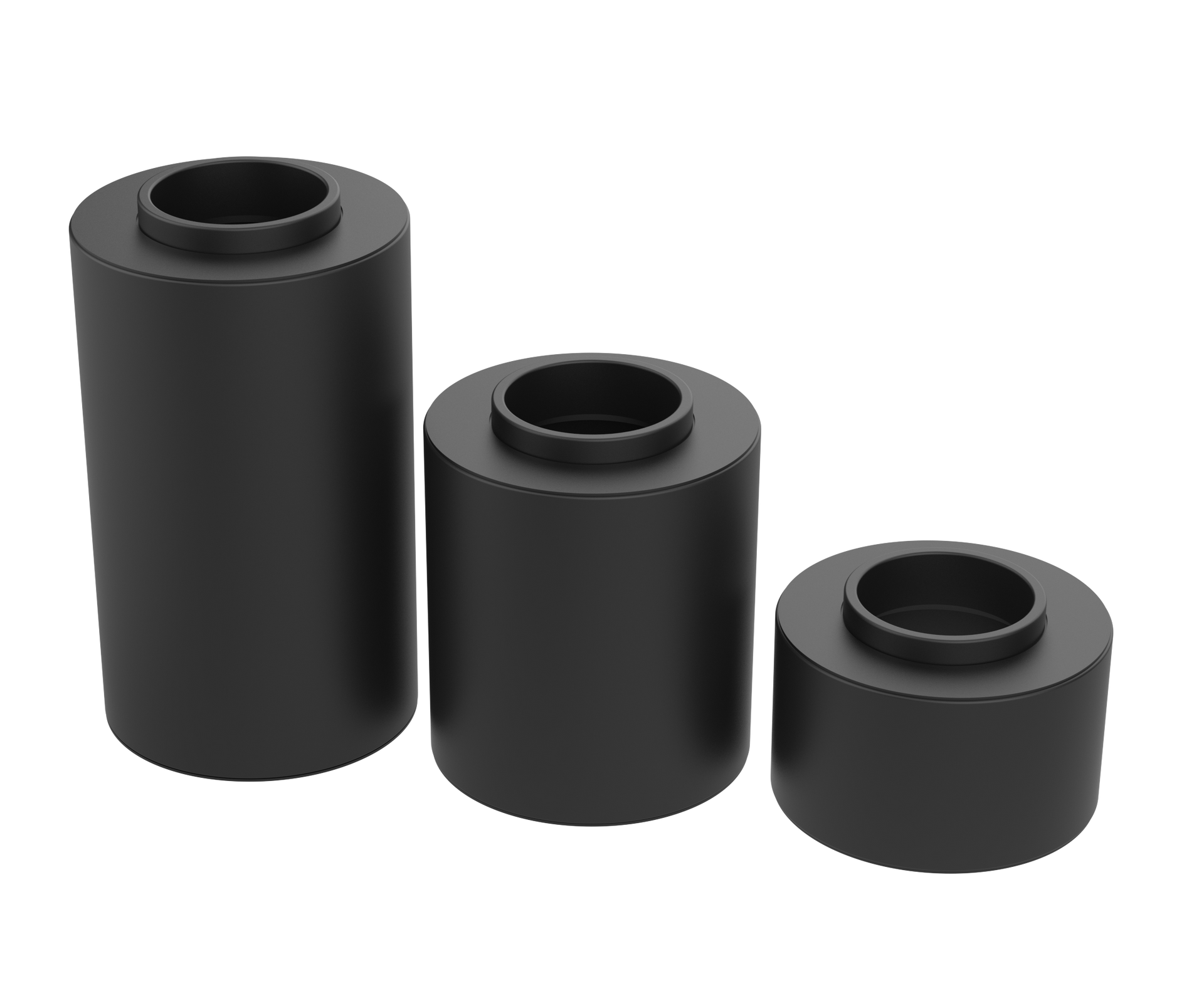

Chuck Extensions are offered in size incremental lengths of 1.50”, 1.00”, and 0.50”.

BullseyeBore Core Chuck Extensions are especially helpful with longer drill bits (5”- 8”) when the entire length of the drill bit will not be used during the drilling operation. The area also helpful with longer specialty drill bits like Spade and Auger drill bits. This video depicts BullseyeBore Core with several different length Chuck Extensions and bits as well as the attachment process.

Some experimentation may be required to select the optimally sized Chuck Extension. This may be accomplished by visualizing the pattern on a worksurface with the target drill bit and different size Chuck Extensions installed. Chuck Extensions are offered in size incremental lengths of 0.50”, 1.00”, and 1.50”.

Always read and follow the

BullseyeBore Core Safety Guidelines before attempting to use BullseyeBore Core or any BullseyeBore Core accessories on a drill or in an actual drilling operation.

Like BullseyeBore Core, Chuck Extensions connect magnetically to the drill chuck face. BullseyeBore Core then engages magnetically with the front of the Chuck Guide. The Chuck Guide also contains an extended ring that inserts into the BullseyeBore Core to prevent displacement between BullseyeBore Core and the Chuck Extension.

No, only a single BullseyeBore Chuck Extension may be used on a drill chuck at any one time, and BullseyeBore Core Chuck Extensions should NEVER be stacked on a drill chuck. Stacked BullseyeBore Chuck Extensions can lead to potentially unstable and/or unsafe rotation of both BullseyeBore Core and the Chuck Extension(s) on the drill chuck. Further, stacked BullseyeBore Chuck Extensions may also contribute to inaccurately projected alignment patterns on the worksurface.

Chuck Extensions work with most common keyed and keyless drill chucks on commercial drills that can accept 0.5” diameter drill bits. Here is a general list of drill type and drill chuck compatibility conditions for Chuck Extensions:

- The drill chuck has a round, metallic, flat face of greater than or equal to 0.65" diameter

- The drill chuck has a bit hole of less than or equal to 0.56" diameter and larger than or equal to 0.414"

- The drill has a maximum RPM equal to or less than 2500 RPM

Here is a general list of Chuck Extension incompatible drill types and drill chucks:

- Chuck Extensions are incompatible with drill chucks that have smaller diameter faces, such as those that require use of a Standard Chuck Guide. Do not use Chuck Extensions with drill chucks that have smaller diameter faces and/or require use of a Standard Chuck Guide.

- Chuck Extensions are incompatible with Hex Shank drill chucks. Do NOT attempt to use Chuck Extensions with Hex Shank drill chucks.

- Chuck Extensions are incompatible with pneumatic drills due to the fast rotational acceleration of pneumatic drills and or the smaller diameter faces that are typically incorporated onto pneumatic drills. Do NOT use or attempt to use Chuck Extensions with pneumatic drills.

For more guidance on Chuck Extension compatibility on different drills and chucks, please refer to the

BullseyeBore Core Product and Accessory Compatibility Guide in the BullseyeBore Core product page. Further, always read and follow

BullseyeBore Core Safety Guidelines before attempting to use BullseyeBore Core or any BullseyeBore Core accessories on a drill or in an actual drilling operation.

No, you do NOT need a Standard Chuck Guide on BullseyeBore Core when using a Chuck Extension. Chuck Extensions connect magnetically to BullseyeBore Core and have an extended ring that inserts into BullseyeBore Core to prevent displacement between BullseyeBore Core and the Chuck Extension.

BullseyeBore Core Worksurface Extension Plates are an optional accessory in the BullseyeBore Core accessory ecosystem.

A BullseyeBore Core Worksurface Extension Plate is a flat aluminum circular plate that can be either held in place or tacked in place on the flat worksurface to “extend” it so the worksurface patterns are fully visible. Worksurface Extension Plates “extend” a small worksurface so the Reference Pattern and at least one Alignment Pattern is visible.

The plates has a 6” diameter with the BullseyeBore logo on one side and nothing on the other.

The simplest way to utilize a Worksurface Extension Plate on a small worksurface is to position it flat on the worksurface so that the intended drill bit hole is positioned within center of the open Worksurface Extension Plate hole. You can optionally use your free hand to hold the Worksurface Extension Plate in place prior to and during drilling operations, or the Worksurface Extension Plate can be tacked onto the worksurface prior to and during drilling operations. In any drilling operations, it is critical for safety purposes to always keep your hands clear of the drill bit while using BullseyeBore Core. Always read and follow the BullseyeBore Core Safety Guidelines before attempting to use BullseyeBore Core or any BullseyeBore Core accessories on a drill or in an actual drilling operation.

In the two images below, the Worksurface Extension Plate is held in place by a free hand. This can be somewhat challenging if you must also hold the workpiece itself in place (as was done in the images). Please note that for safety purposes the free hand holding the Worksurface Extension Plate should be positioned far from the drill bit and protected by a glove. Always remember that safety is critical when using any power tools such as power drills.

Core Green Extended with a 6” Worksurface Extension Plate

Core Red Extended with a 6” Worksurface Extension Plate

Instead of using your free hand to hold the Worksurface Extension Plate in place, it may be alternatively tacked or nailed flat onto the worksurface. This is the recommended procedure for using a Worksurface Extension Plate. Each Worksurface Extension Plate contains eight small holes that can optionally be used with tacks or nails to hold the Worksurface Extension Plate flat in place against a vertical, horizontal, or angled worksurface.

In the following video, the Worksurface Extension Plate is tacked to the high point of the 2x4. Remember that most wooden boards typically have some width-wise camber or curvature, and you must take that into account when positioning the Worksurface Extension Plate. In this video the Worksurface Extension Plate was tacked to the width-wise camber of the 2x4.

The accuracy of any hole drilled with BullseyeBore Core in conjunction with a Worksurface Extension Plate is always dependent on 1) the correct use of BullseyeBore Core, and 2) the correct mounting of the Worksurface Extension Plate with regards to the orientation of the worksurface. If the Worksurface Extension Plate is not perpendicular to the worksurface, then the resulting drill hole will not be perpendicular with regards to the worksurface.